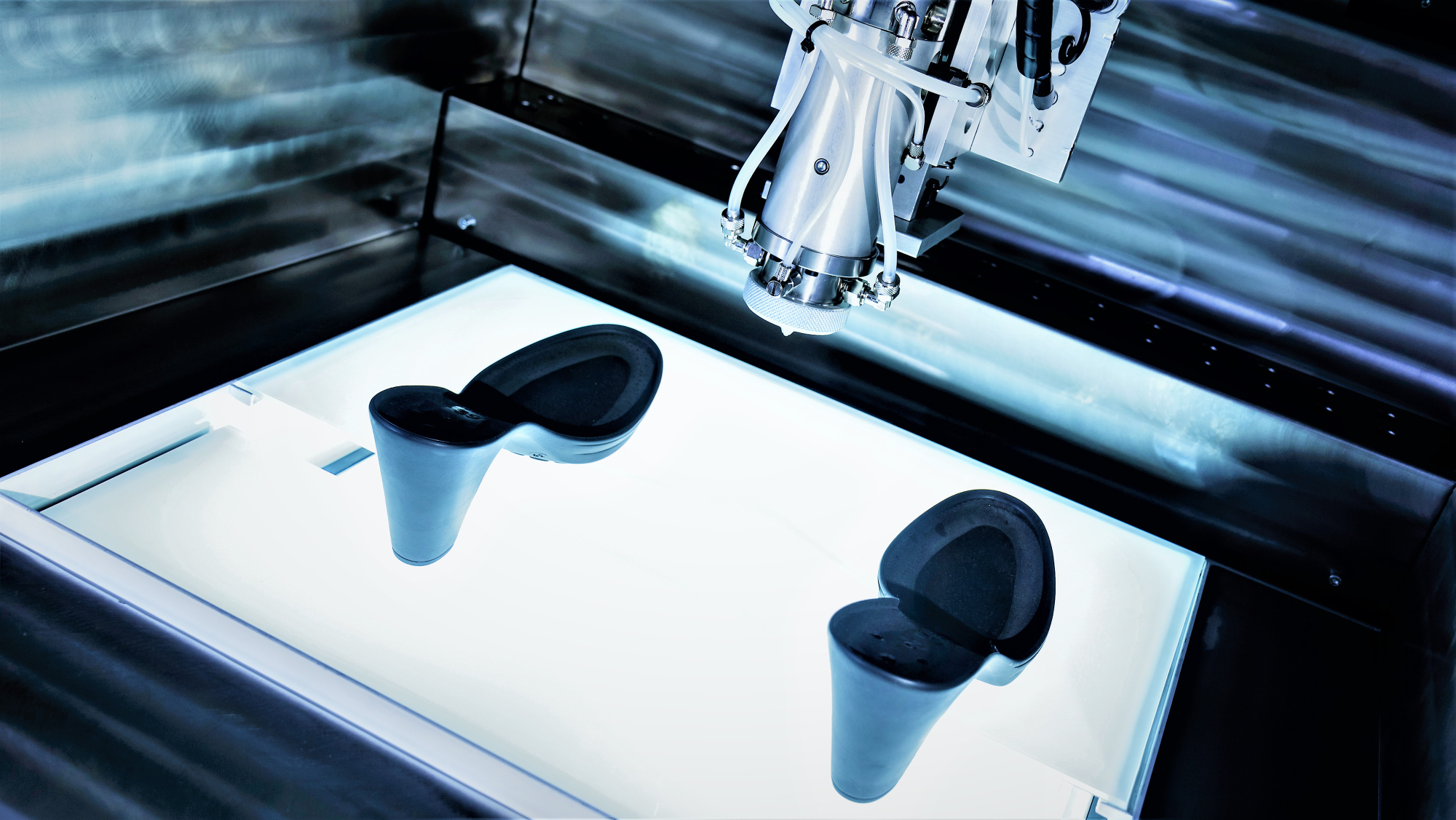

BIDIRECTIONAL PRINTING

The printer is able to mark the insole both vertically and horizontally, combined with the automatic unloading and storage system, which divides the articles by verse and size, making SATURNO 5 the most advanced and versatile automatic cutting system of its kind .

WATER COOLING

The definitive solution to the problems of welding by thermoforming of thermoplastic materials cut into multilayer mode.

INTEGRATED OPTICAL VISION SYSTEM

Both on SATURNO 3 and on SATURNO 5 it is now possible to manually nest the pieces directly on the machine, eliminating all material waste.

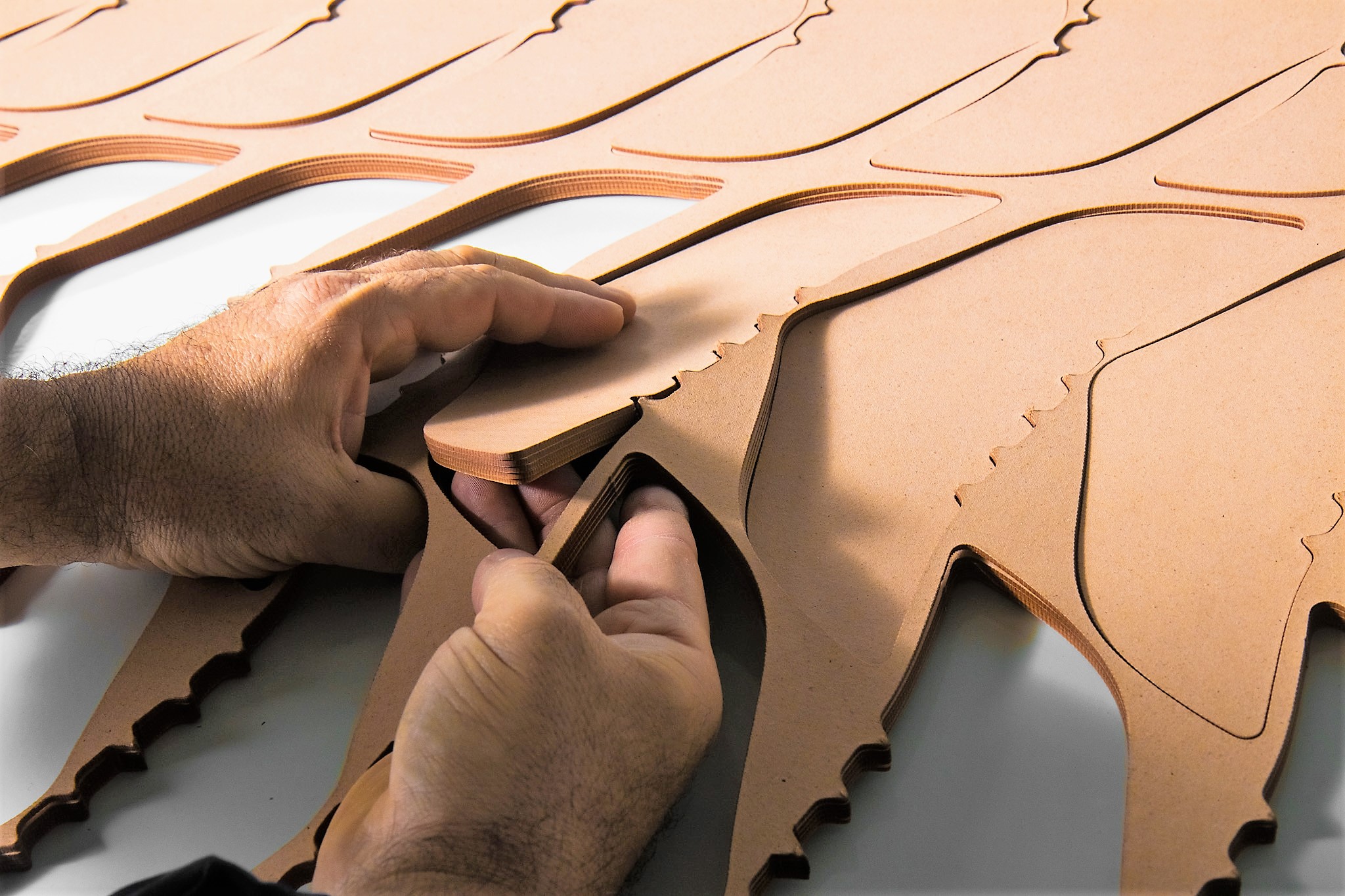

MULTI LAYER CUT

The high precision of the cutting in multilayer mode up to 10 mm, is made possible thanks to the various technologies used. The cutting between pressure rollers, the rigid plane and the mechanical locking system, are the main secrets that lie behind the cut perfectly in the template that we are able to obtain.

bis.jpg)

THICKNESS UP TO 35mm

Micro, leather, cardboard, fibers, tunit or neoprene are just some of the materials we can cut. The cut is completed with a single pass even in materials with thickness up to 35mm. The accuracy and speed, even in this case, remain our and your priorities.

PRESSORIES ROLLERS

The integrated pressure rollers in all our cutting systems represent the turning point from all points of view. The rollers, placed on the sides of the cutting tool, allow us: the reduction or cancellation of costs related to the energy consumption of the vacuum system, the possibility of cutting on a rigid surface to obtain a cut perfectly in the template in both sides of the product, the elimination of the "skidding" effect and the forced flattening of the deformed materials.