Spektro

Virtual warehouse for insole molds

A more and more demanding and personalized modeling, requires a high quantity of molds for the shaping of the insoles; especially in the women's line.

Combining a new last line with molds already supplied to the insole is a task that requires concentration, memory and competence on the part of the operator.

Spektro helps with this through the following procedure:

PHASE 1 Memorization of the profiles of all the molds in possession by scanning.

PHASE 2 Scan of the shape of the insole to be made.

PHASE 3 Spektro detects and indicates the type of mold to be used among those stored in the system.

PHASE 4 The operator recognizes the mold and takes it from the physical warehouse.

For the company, all this translates into: SAVING of time and money as it allows to avoid the possible construction of a new mold

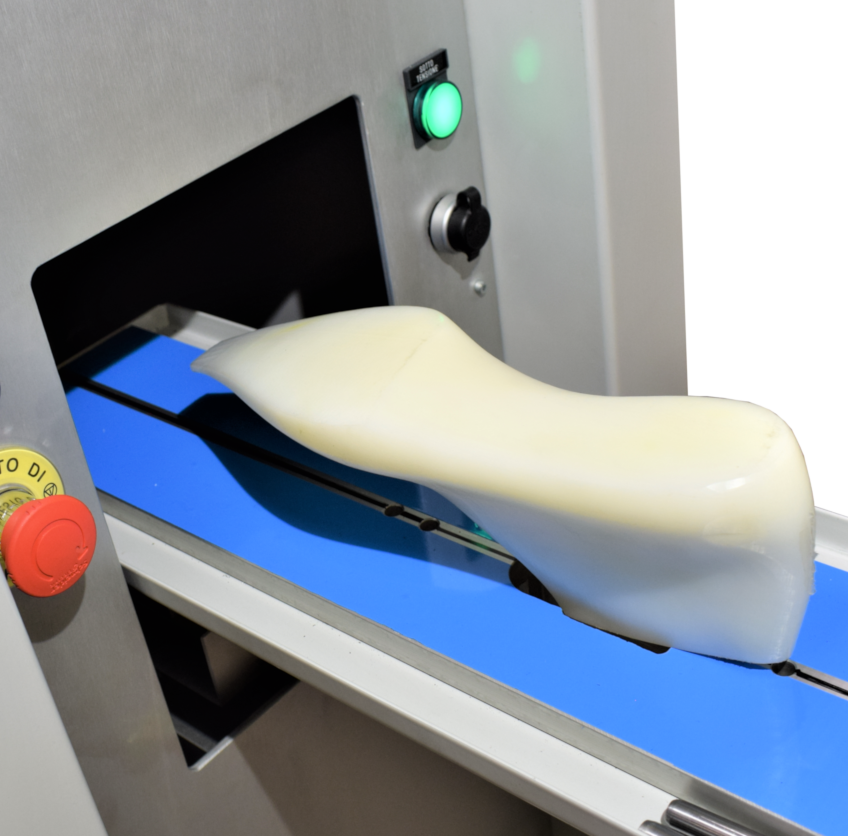

Scan a shape

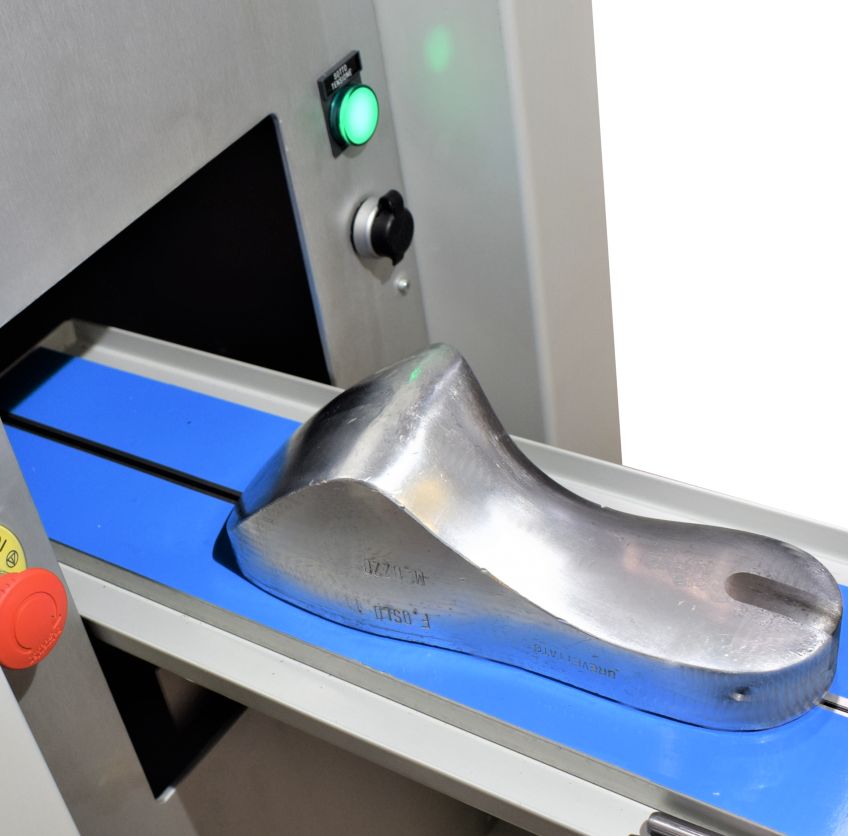

Scanning a mold

Technical details

| Voltage: | 230 V 40HZ |

|---|---|

| Power: | 0.3 KW |

| Dimensions: | 1,75 X 75 X h 55 mt |

| Weight: | 140 KG |

Documentations

| Title | Description | Access level | Download |

|---|---|---|---|

|

|